RMD believes that quality is the most important part of making metal parts. The Quality department is in place to ensure that all of the tolerance requirements and surface finish requirements are met per customer design.

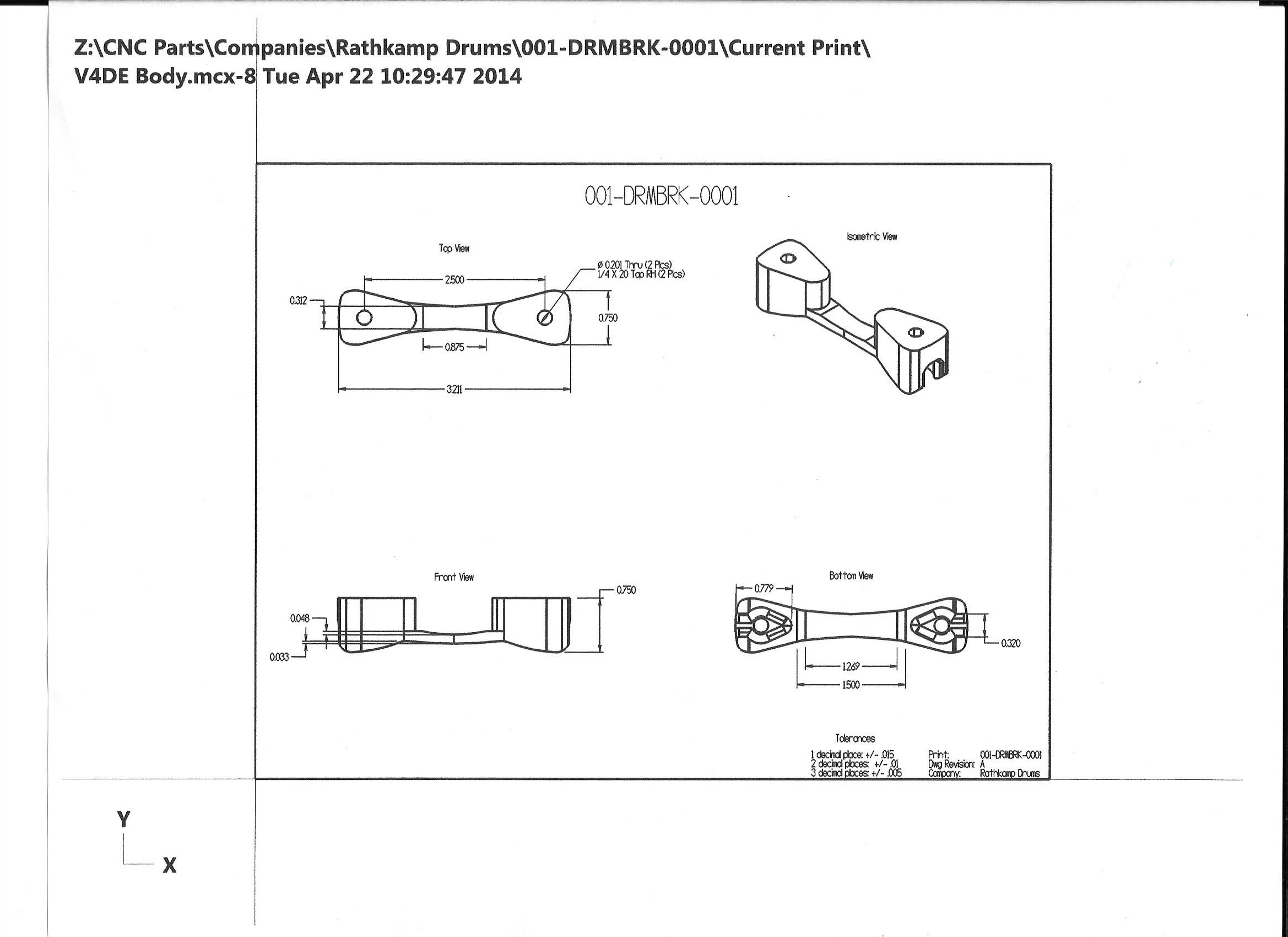

The RMD Engineering team will work with you to create a functional 3D model before sending the part to the production floor or prototyping lab. After the 3D model is created, the Design team will create a 2D dimensioned print highlighting the features with necessary tolerances specified on the print. This process ensures that all RMD parts are made based on customer specifications for quality.

Design Engineering Services

The second option for quality is to send in a 3D model or 2D dimensioned print to our sales team for quotation. The sales team will then send the model to the Engineering team to be machined based on the model dimensions. The quality will be based on the tolerances specified in the file when it is sent to the Sales team. (RMD will work with your Engineering team to ensure that the correct version of the file is being machined before machining begins.)

Send CAD DrawingRMD features Haas' Wireless Intuitive Probing System Renishaw wireless tool-setting probe and Renishaw wireless work offset probe. The probe includes macros, spindle orientation and coordinate rotation and scaling. Currently, RMD uses the Intuitive Probing System as well as Calipers, Micrometers, Height Gages, Pin Gages, Go-No-Go Threads, and a variety of other inspection equipment to ensure that customer specified tolerances are held.